Strong Structural Steel Forms the Frame

Galvanized Steel Building Materials Are the Starting Point

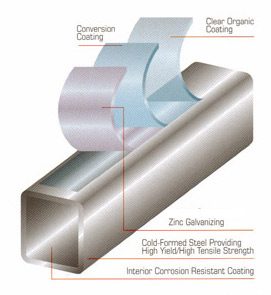

The quality of a premium PWS building begins with the strong, galvanized steel that forms the frame of the building. This mechanical rectangular tubing is high strength galvanized steel produced in conformance with ASTM A513 and with ASTM A500. PWS tri-coat system provides a triple layer of corrosion protection that stands the test of time.

The process begins with cold-rolled steel (CRD) that goes through a process of cold forming and quenching to create greater yield and tensile strength compared to alternative tubing of the same outside dimensions and gauge. After welding, the structural component goes through a three layer coating process.The first layer is a zinc galvanizing layer on both inside and outside the tube, providing it with good corrosion protection. The second coating, the “conversion” coating, protects and seals the zinc galvanizing to improve and lengthen its performance. The final coating is a clear organic film to fully seal the metal from moisture, providing the best rust protection available.

These coatings are then cured to a smooth, hard finish. The result is a smooth, shiny end product with high durability — it will not oxidize or “gray down” with age, nor will the coating flake off during fabrication operations.

Contact PWS today for a review of your building plans, with never an obligation: REQUEST QUOTE